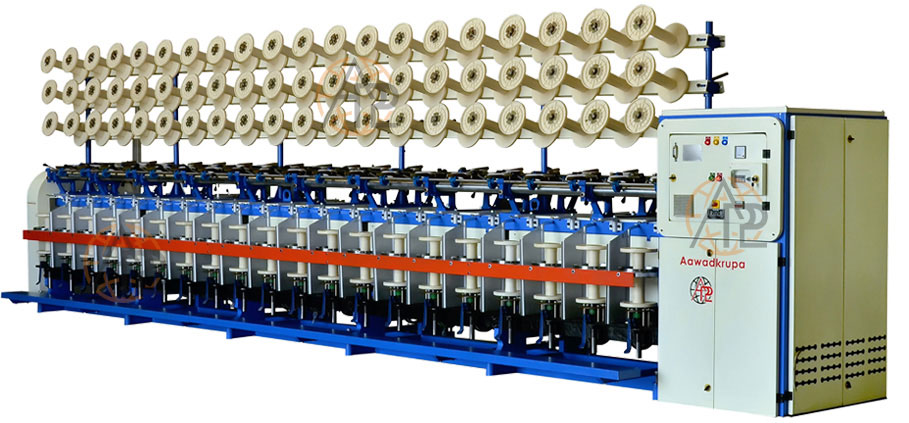

Ring Twister Machine

(Ring Twister Machine is also known as Doubler Machine, Yarn Doubling Machine, Plastic Rope Doubling Machine, Doubler Machine, Online Doubler, Ring Doubler, Yarn Twister Machine)

KEY FEATURES

- User can change automatically TPM setting by PLC & HMI control system instead of manual gear change.

- Best yarn quality & high productivity.

- Uniform counter balancing.

- High speed Ring Twister machine.

- Anti-friction bearing to vital moving parts.

- Optimum production & Easy to operate.

- Spindle Drive heavy duty either special jocky pulley.

- The ring twister is provided with reversible drive that is mainly used for S or Z twisting.

- Effective machine design with ready to use structures at your factory no need to assemble again like other ring twister machine.

- TPM Setting type: Automatic (User push the key paid and change TPM No any mechanical changes).

- Easy movement from one place to another without any kind of dismantling of machine parts.

- Complete powder coated heavy duty structure.

- High speed machine.

- Best yarn quality & high productivity.

- Uniform counterbalancing.

- Anti-friction bearing to vital moving parts.

- Two line roller and heavy duty and hard chromium plating.

- Optimum production, easy of operation, less noisy & less power consumption.

- Heavy duty & Easy movable steel main structure.

- Continuous separator running from spindle rail to delivery.

- Lifting system : Adjustable electronic system with length setting & suspension type ring rails.

- Ring holder : presser die casting with both side oil lubrication points.

- Rigid cast iron body spring loaded steel hook with adjustable type and separate lifting control.

- Synthetic endless type belt.

- Standard switch Gear & R.Y.B Indicator.

- Suitable for foot switch.